Innovative – Ensuring That You Stay Ahead

Research and development plays a major role at S+C. We have to start shaping our future today.

Superior quality – this is the constant challenge that S+C sets itself. Direct contact with our customers, and collaboration with respected research institutes and universities worldwide, help our experts develop market-oriented innovations.

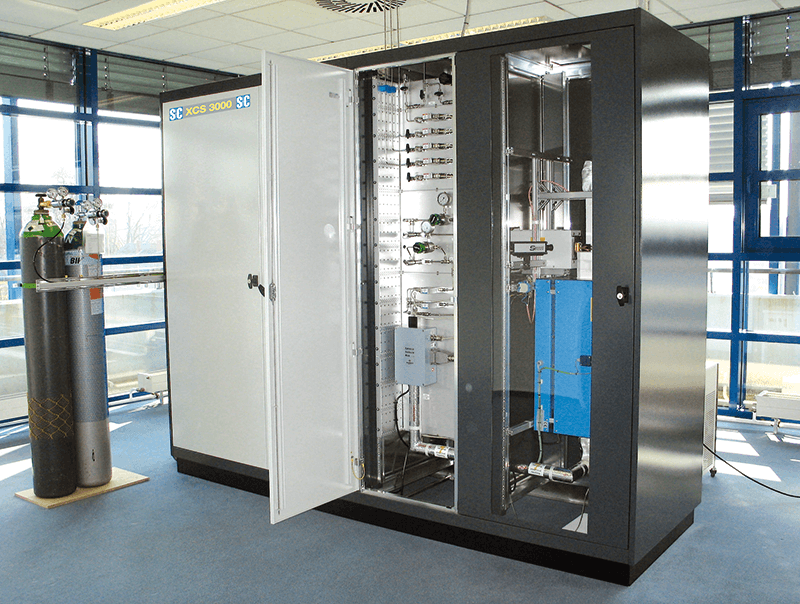

The technological heart of S+C is its Innovation Centre in Lindlar-Kaiserau, Germany (Headquarters). This is where our specialists develop new materials, material combinations and process optimisations. Innovative production processes often originate from our Innovation Centre. Our goal is to consistently offer the best available technology.

S+C’s Testing and Laboratory Centre, certified to DIN EN ISO/IEC 17025:2005, has for many years been a neutral body for the development, testing, examination and classification of materials. All tests can be monitored by approval and classification organisations such as the TÜV, LRS, GL or a company’s own approval and quality assurance departments.